Our view on a Progress functionality for commissioning

Often the only control instrument for commissioning is a planning application.

But is such a package sufficient to get grip on the typical activities of the commissioning pro-cess?

No.

The nature of the commissioning phase is, as far as possible, to determine if components and systems match the requirements and if not, to solve them.

Assuming that organizations learn from previous engineering and production errors, only unknown errors should occur. Otherwise they would have solved the errors systematically.

But how does the commissioning phase become manageable and controllable if errors cannot be planned?

Since the reality is that you can never achieve a state of 100% flawlessly engineered and produced product, the engineering and production department must be able to learn from the commissioning phase.

Without collecting data and analyzing this data, the organization will continuously (re) produce errors. In addition to a planning tool, another system is also required.

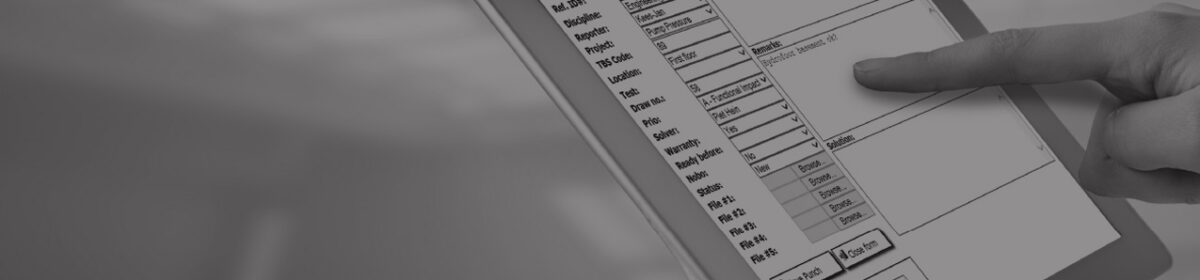

A system that makes it possible to collect data up to component and system level. This implies that test questions, from which data is generated, must be set at component and system level. Required data can be divided into:

- Recording of measured values (Accepted)

- Recording of measured values and captured information on deviations if the measured va-lues do not meet the set standard. (Not Accepted)

In the context of achieving the planning, a good solution process for errors (punches) is a critical success factor. This solution process must follow a fixed pattern in which stakeholders have their own role and responsibility assigned.

Just as in a financial process, the roles of cashier and bookkeeper are separated, activities in the commissioning process also must be divided. The role that solves a punch is a different role than the role that determines or accepts that the solution meets a set standard.

Distinguishing successive roles;

- Distinguishing successive roles;

- test executor,

- punch assessor,

- punch solver (multiple disciplines possible)

- punch solution checker.

Roles can be assigned to internal but also external parties.

In order to be able to follow the punch solution process efficiently, it is vital to note additional data such as;

- which Surveyor (client or certifying body) determines the residual point

- priority on solution of a punch

- which discipline is responsible for the punch (e.g. electric or hydraulic)

- photo of a punch (reference info)

The solution process, and in particular the insight into who owns which activity, ensures: - increased user involvement and sense of responsibility

- Acceleration of the solution process

All information and reports must be readily available and real-time in a multi-user Cloud data-base. The tool enables you to steer on the solution process of punches and generates data in order to learn from mistakes (fail fast).

Complementing the planning with such a system ensures that the planning can be achieved more easily as it is more evident what needs to be done in case of a deviation.